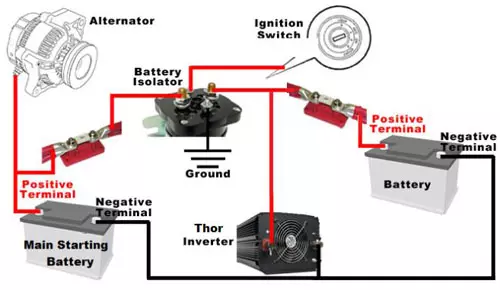

A truck power inverter wiring diagram is a visual representation of how to connect the inverter properly. It shows the wiring connections for the inverter, battery, and other components.

This diagram helps ensure the correct installation and operation of the power inverter in your truck, preventing any electrical issues and ensuring optimal performance. By following the wiring diagram carefully, you can safely and effectively set up the power inverter in your truck, allowing you to power various devices and appliances while on the road.

Proper wiring is crucial for the inverter to function correctly and avoid any potential hazards. Let’s delve deeper into the importance and specifics of truck power inverter wiring diagrams.

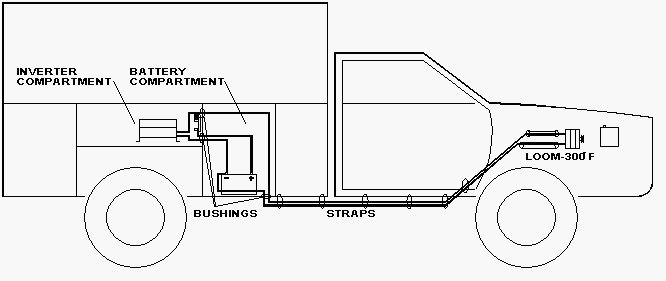

Credit: www.magnum-dimensions.com

Benefits Of A Truck Power Inverter

A truck power inverter wiring diagram can provide numerous benefits for truck owners. It can convert DC power from the truck’s battery to AC power, allowing you to use electronic devices and appliances while on the road. This can save you money on hotel stays and provide added convenience during long trips.

Benefits of a Truck Power Inverter Truck power inverters are a valuable addition to any vehicle, providing a range of benefits that enhance convenience, versatility, and emergency preparedness. Understanding the advantages of a truck power inverter can help drivers make the most of this essential piece of equipment. ConvenienceConvenience

Truck power inverters offer unparalleled convenience by allowing drivers to power electronic devices and appliances while on the road. Whether it’s charging a laptop, running a small refrigerator, or using power tools, truck power inverters enable drivers to access the electricity they need for various applications. VersatilityVersatility

With the ability to convert DC power from the vehicle’s battery into AC power, truck power inverters are incredibly versatile. This feature enables drivers to use a wide range of electronic devices and appliances that would typically require a standard electrical outlet. From laptops and smartphones to small kitchen appliances, the versatility of truck power inverters makes them indispensable for drivers who need to power different devices on the go. Emergency Power SourceEmergency Power Source

In addition to providing convenience and versatility, truck power inverters serve as a reliable emergency power source. In the event of a power outage or emergency situation, a truck power inverter can be a lifesaver, allowing drivers to charge essential devices, operate emergency lighting, or power critical equipment. In conclusion, truck power inverters offer unparalleled convenience, versatility, and emergency preparedness for drivers on the road. Understanding the benefits of these devices is essential for making the most of their capabilities.Understanding The Wiring Diagram

Understanding the wiring diagram of a truck power inverter is essential for safe and efficient installation. The diagram provides a visual representation of the electrical connections and components involved, guiding you through the process of setting up the inverter system. Let’s explore the key aspects of the wiring diagram to ensure a thorough understanding.

Components Involved

The wiring diagram outlines the various components essential for the truck power inverter system. These may include the inverter unit, battery, fuse, switches, and power outlets. Each component is represented with specific symbols and labels, providing a clear overview of the entire setup.

Electrical Connections

The wiring diagram illustrates the intricate electrical connections between the different components. It details the positive and negative terminals, grounding points, and interconnections required for seamless functionality. Understanding these connections is crucial for ensuring proper power flow and preventing potential hazards.

Tools And Materials Required

When it comes to installing a truck power inverter, having the right tools and materials is crucial for a successful wiring process. The correct equipment will ensure a safe and efficient installation, allowing you to power your devices while on the road. Here’s a breakdown of the tools and materials you will need to complete the wiring of a truck power inverter.

Key Tools

- Wire Strippers: Essential for removing insulation from wires.

- Wire Cutters: Used to cut wires to the required length.

- Screwdriver Set: Includes flathead and Phillips screwdrivers for securing connections.

- Multimeter: Helps to test for continuity and voltage.

- Drill and Bits: Necessary for creating holes to mount the inverter.

- Crimping Tool: Used to attach terminals to the wires securely.

- Tape Measure: Aids in measuring and cutting wires accurately.

Recommended Materials

- Electrical Tape: Provides insulation and protection for wire connections.

- Heat Shrink Tubing: Offers additional protection for wire splices.

- Terminal Connectors: Used to create secure connections between wires and components.

- Wire Nuts: Assist in joining and insulating wires together.

- Cable Ties: Help organize and secure wires in place.

- Inverter Kit: Includes necessary cables and connectors for the specific inverter model.

- Mounting Hardware: Bolts and screws for securing the inverter in place.

Credit: www.pinterest.com

Pre-installation Steps

When it comes to installing a truck power inverter, there are several crucial pre-installation steps to ensure a successful and safe setup. These steps involve assessing power needs and implementing safety precautions to prevent any mishaps. By following these steps, you can confidently proceed with the wiring process.

Assessment Of Power Needs

Before beginning the installation, it’s essential to assess the power requirements of the devices you intend to run with the inverter. Make a list of all the electrical equipment, including their wattage and amperage ratings. This information will guide you in selecting the appropriate inverter size to meet your power needs.

Safety Precautions

Prioritize safety by taking necessary precautions before handling any electrical components. Ensure the truck’s electrical system is turned off to avoid the risk of electric shock. Use insulated tools and wear protective gear, such as gloves and safety goggles, to shield yourself from potential hazards. Additionally, familiarize yourself with the truck’s wiring diagram to understand the layout and connections.

Installation Process

The installation process of a truck power inverter involves following a detailed wiring diagram for correct setup. Ensuring proper connections and wire placements is crucial for optimal performance and safety. Properly wiring the inverter will help maximize its efficiency and functionality on the road.

Locating The Inverter

Place the inverter in a well-ventilated area near the battery.

Ensure it’s easily accessible for wiring and maintenance.

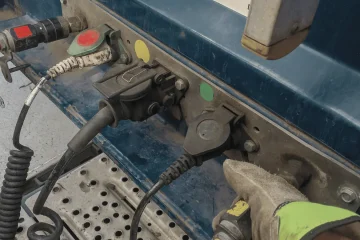

Connecting To The Battery

Disconnect the battery to avoid any electrical mishaps.

Connect the inverter’s positive cable to the positive battery terminal.

Connect the inverter’s negative cable to the negative battery terminal.

Use appropriate gauged cables for efficient power flow.

Testing And Troubleshooting

Test and troubleshoot truck power inverter wiring diagrams for optimal performance and reliability. Ensure proper connections and voltage levels for seamless operation on the road. Identify and resolve any wiring issues promptly to prevent power disruptions during travel.

Initial Testing When setting up a truck power inverter, initial testing is crucial. Follow these steps to ensure proper installation: 1. Check the wiring diagram for accuracy. 2. Verify all connections are secure. 3. Test the inverter with a multimeter. Common Issues and Solutions Facing problems with your truck power inverter? Here are some common issues and solutions to consider: – No power output: Check connections. – Overheating: Ensure proper ventilation. – Fuse blows: Replace with correct amperage. Remember, regular maintenance is key to a well-functioning inverter.Maintenance Tips

To ensure proper functionality of your truck power inverter, it is crucial to have a well-designed wiring diagram. Follow manufacturer instructions carefully and double-check all connections to avoid any potential issues. Regular maintenance checks can help prevent future problems.

Maintenance Tips Regular Inspection Regularly inspect the power inverter wiring to identify any loose connections or damaged wires. Loose connections can lead to inefficiency and potential safety hazards. Use a multimeter to test the voltage and ensure it is within the manufacturer’s recommended range. Cleaning and Care Keep the inverter and its wiring clean and free from debris or corrosion. Use a soft brush to remove any accumulated dirt or dust. Inspect the wiring for any signs of corrosion and use a wire brush to gently remove it. Apply a small amount of dielectric grease to the terminals to prevent corrosion. By following these maintenance tips, you can ensure that your truck power inverter wiring remains in optimal condition, providing reliable power conversion when needed.

Credit: www.oksolar.com

Frequently Asked Questions

How To Connect Power Inverter To Truck Battery?

To connect a power inverter to a truck battery, first, turn off the inverter and disconnect it from the battery. Next, connect the positive (+) terminal of the inverter to the positive terminal of the battery, and then connect the negative (-) terminal of the inverter to the negative terminal of the battery.

How Do You Wire An Inverter To A Battery?

To wire an inverter to a battery, connect the positive terminals first, then the negative terminals. Use appropriate gauge cables for safety and efficiency. Double-check connections to ensure proper polarity.

What Should You Not Plug Into An Inverter?

Avoid plugging in high-powered appliances like AC units, refrigerators, or power tools into an inverter. It can damage the equipment.

How To Connect An Inverter To A Main Supply?

To connect an inverter to the main supply, turn off the main power, connect the inverter to the battery, and then connect the inverter’s output to the main supply. Finally, turn on the main power and the inverter. Be sure to follow safety precautions.

Conclusion

Understanding the wiring diagram for your truck power inverter is essential for a successful installation and operation. Following the manufacturer’s instructions and consulting with a professional can help avoid any potential safety hazards. Taking the time to properly wire your inverter can ensure reliable power supply for all your needs on the road.

Remember to always prioritize safety and caution when handling electrical components.