A diesel heater works by burning diesel fuel to produce heat using a combustion process. Diesel heaters are a popular choice for providing warmth in various settings, from homes to outdoor events.

These heaters operate by burning diesel fuel to generate heat. The fuel is injected into a combustion chamber and mixed with air, creating a controlled flame. The heat produced is then transferred to a heat exchanger, which warms the surrounding air.

This warm air is then circulated through the space, providing efficient and reliable heating. Diesel heaters are highly efficient and can quickly warm large areas, making them a popular choice for diverse heating needs. We will explore the inner workings of diesel heaters and their advantages for different applications.

Credit: www.vvkb.com

History Of Diesel Heaters

When it comes to understanding the history of diesel heaters, delving into their early development and evolution over time is essential. This is a fascinating journey that sheds light on the ingenuity and innovation behind these indispensable heating devices.

Early Development

The roots of diesel heaters can be traced back to the early 20th century, when Rudolf Diesel, the inventor of the diesel engine, conceptualized the idea of utilizing surplus diesel fuel for heating purposes. His vision was to create an efficient, cost-effective heating solution that could cater to various industrial and residential needs.

Evolution Over Time

Throughout the years, diesel heaters have undergone significant evolution, adapting to the changing technological landscape and the increasing demand for more efficient and eco-friendly heating solutions. From their initial rudimentary designs to the modern, sophisticated models, diesel heaters have continually improved in terms of performance, energy efficiency, and environmental sustainability.

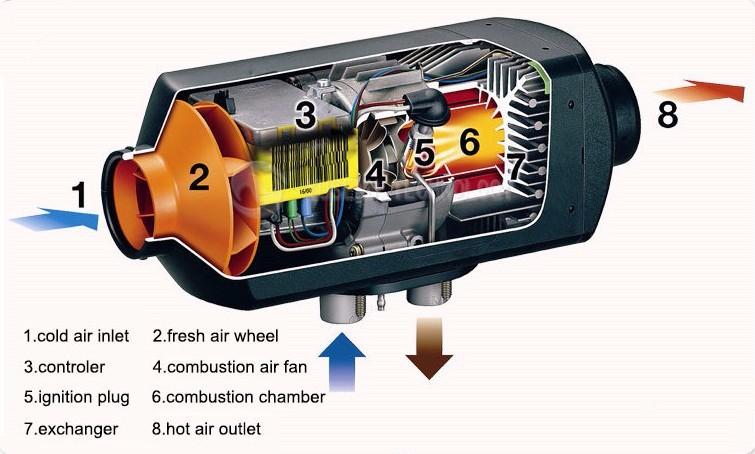

Components Of A Diesel Heater

When it comes to understanding how a diesel heater works, it’s important to examine its various components. The components of a diesel heater include the burner unit, fuel system, and ignition system. Each of these components plays a crucial role in the operation of the heater, ensuring efficient and reliable heating in various settings.

Burner Unit

The burner unit is the heart of a diesel heater. It is responsible for combusting fuel to produce heat. This unit consists of a combustion chamber, a heat exchanger, and a blower. The combustion chamber is where the fuel is mixed with air and ignited, creating a flame. The heat exchanger transfers the heat from the flame to the surrounding air, and the blower circulates the heated air throughout the space.

Fuel System

The fuel system of a diesel heater is responsible for delivering diesel fuel to the burner unit. It typically consists of a fuel tank, a fuel pump, a fuel filter, and a fuel line. The fuel tank stores the diesel fuel, while the fuel pump draws the fuel from the tank and delivers it to the burner unit. The fuel filter removes any impurities or contaminants from the fuel, ensuring clean and reliable combustion. Finally, the fuel line transports the fuel from the pump to the burner unit.

Ignition System

The ignition system of a diesel heater is responsible for initiating the combustion process. It ensures that the fuel-air mixture in the combustion chamber is ignited at the right time and in the right place. The ignition system typically consists of an ignition coil, a spark plug, and an electronic control unit (ECU). The ignition coil generates a high-voltage electrical spark, which is delivered to the spark plug. The spark plug then ignites the fuel-air mixture, starting the combustion process. The ECU controls the timing and duration of the spark, optimizing the efficiency of the ignition process.

Working Principle Of A Diesel Heater

A diesel heater is an efficient and reliable solution for providing warmth in various settings, including homes, offices, and vehicles. Understanding the working principle of a diesel heater can help you appreciate its functionality and make informed decisions about its usage. In this article, we will explore the fuel combustion process and the heat transfer mechanism that powers a diesel heater.

Fuel Combustion Process

The fuel combustion process is the core mechanism that allows a diesel heater to generate heat. It begins with the intake of diesel fuel into the heater’s combustion chamber. The fuel is then atomized into fine droplets using a nozzle, ensuring better mixing with air. The combustion chamber contains a glow plug or an electric heating element that ignites the mixture, resulting in the controlled combustion of the fuel-air mixture. This combustion process releases a significant amount of heat energy.

The generated heat energy is then used to warm up the air within the heater. This warm air is then circulated through air ducts or vents, distributing the heat throughout the desired space. The combustion process continues as long as fuel is supplied to the heater, allowing for sustained heating.

Heat Transfer Mechanism

The heat transfer mechanism plays a crucial role in the efficiency of a diesel heater. Once the fuel undergoes combustion, the heat energy produced is transferred to the surrounding components of the heater. The heat exchanger, typically made of stainless steel or another conductive material, absorbs the heat energy from the combustion chamber and transfers it to the circulating air.

The heat exchanger consists of a series of tubes or finned surfaces that provide a large surface area for effective heat transfer. As the cool air passes through these heated surfaces, it gets warmed up through conduction. This warm air then flows into the desired area, raising the ambient temperature and providing comfortable warmth.

Key Takeaways:

- A diesel heater operates through the fuel combustion process and heat transfer mechanism.

- The fuel combustion process involves atomizing diesel fuel, igniting the mixture, and generating heat energy.

- Heat energy is transferred to the surrounding components, specifically the heat exchanger.

- The heat exchanger then warms up the circulating air through conduction, providing warmth to the desired space.

Understanding the working principle of a diesel heater can help you make informed choices when it comes to selecting and using this efficient heating solution. By harnessing the power of fuel combustion and heat transfer, diesel heaters can provide reliable and economical warmth in a variety of settings.

Comparing Diesel Heaters To Other Heating Systems

A diesel heater operates by burning diesel fuel and circulating the heated air through a heat exchanger. This process is efficient and cost-effective, especially compared to electric or propane heaters. Diesel heaters are a popular choice for boats, RVs, and remote cabins due to their reliability and ability to generate consistent heat.

Comparing Diesel Heaters to Other Heating Systems Diesel heaters have gained popularity in recent years as an efficient and cost-effective way to heat our homes and workplaces. But how do they compare to other heating systems? Let’s examine the efficiency levels and environmental impact of diesel heaters in comparison to traditional heating methods.

Efficiency Levels

When it comes to efficiency, diesel heaters excel in providing warmth quickly and effectively. These heaters use a combustion process that maximizes energy output, ensuring that a large percentage of the fuel is converted into heat. Most diesel heaters boast an efficiency level of around 90% or higher, making them highly efficient. In comparison, electric heaters typically have an efficiency level of 100% but are often more expensive to operate due to the higher cost of electricity.

Environmental Impact

Considering the environmental impact, diesel heaters come with both advantages and challenges. On one hand, they emit less greenhouse gases compared to other fossil fuel-based heating systems like oil or gas heaters. However, they do release nitrogen oxide (NOx) and carbon monoxide (CO) into the atmosphere, which can contribute to air pollution and pose health risks if not properly ventilated. To mitigate these concerns, modern diesel heating systems are equipped with advanced technologies such as combustion detectors, flame sensors, and exhaust gas recirculation systems. These components work together to minimize emissions and ensure the safe and efficient operation of the diesel heater. It is also worth noting that diesel fuel itself can have an environmental impact during the extraction, production, and transportation stages. However, advancements in fuel purification and quality control have helped to reduce these impacts over time. In conclusion, diesel heaters offer high efficiency levels in terms of converting fuel into heat. While they do have some environmental impact, modern diesel heaters are designed with safety measures and emission-reducing technologies to minimize their footprint. By taking these factors into consideration, you can make an informed decision when choosing a heating system that best suits your needs.

Applications Of Diesel Heaters

Diesel heaters use a combustion process to generate heat, where diesel fuel is burned to warm the air. This hot air is then circulated through a system to provide warmth in various applications. Diesel heaters are commonly used in vehicles, RVs, boats, and outdoor spaces for efficient heating solutions.

Diesel heaters are versatile devices used in various settings due to their efficiency and effectiveness in providing heat. Let’s explore the diverse applications of diesel heaters.

Residential Use

In homes, diesel heaters are commonly used for supplemental heating in areas with extreme cold. They are ideal for heating garages, workshops, or basements, providing warmth quickly and efficiently.

Commercial And Industrial Settings

Diesel heaters are indispensable in commercial and industrial environments. They are utilized for drying paint in automotive shops, thawing frozen pipes, and maintaining optimal temperatures in warehouses.

Credit: www.vmacs.net

Benefits Of Using A Diesel Heater

Keeping your space warm during cold weather is essential, and diesel heaters are an effective solution. They offer several advantages that make them a popular choice for heating needs. Below are some key benefits of using a diesel heater:

Cost-effective Heating Solution

Diesel heaters are known for their efficiency in heating spaces while consuming less fuel compared to other heating options. This results in cost savings on fuel expenses, making them a budget-friendly choice for heating solutions. They provide reliable heating without breaking the bank.

Reliability And Durability

Diesel heaters are renowned for their reliability and durability. They are designed to operate efficiently even in harsh conditions, offering consistent heating performance. Their robust construction ensures longevity, requiring minimal maintenance and providing peace of mind knowing that your heating system is dependable.

Maintenance Tips For Diesel Heaters

When it comes to ensuring the efficient and safe operation of diesel heaters, regular maintenance is essential. By following some key maintenance tips, you can prolong the life of your diesel heater, minimize the risk of breakdowns, and maintain its effectiveness. Let’s explore some important maintenance practices for diesel heaters, including regular cleaning and checking for leaks.

Regular Cleaning

Regular cleaning of your diesel heater is crucial for its optimal performance. The accumulation of dirt, dust, and soot can impede the heater’s efficiency and pose a fire hazard. To keep your heater functioning smoothly, clean the combustion chamber, heat exchanger, and exhaust system regularly. Use a soft brush to remove any debris and clear any blocked air vents. Additionally, check and clean the fuel nozzles to ensure proper fuel atomization.

Checking For Leaks

Periodically inspect your diesel heater for any signs of fuel or exhaust leaks. Visually examine the fuel lines for any cracks or signs of wear and tear, and ensure all connections are tight and secure. Look for any sooty residue around the exhaust system, which can indicate a leak. Test the exhaust system for leaks by conducting a smoke test, and promptly address any leaks to prevent the risk of carbon monoxide exposure.

Credit: warmda.com

Frequently Asked Questions

Can You Sleep With Diesel Heater On?

Sleeping with a diesel heater on is not recommended for safety reasons. Carbon monoxide poisoning risk increases.

How Does A Diesel Powered Heater Work?

A diesel powered heater uses diesel fuel and a heating element to generate heat for warmth.

How Long Will A Diesel Heater Run On A Tank Of Fuel?

A diesel heater can run for approximately 24-48 hours on a tank of fuel, depending on the size of the tank and the heater’s settings. Regular maintenance can also affect the running time.

Do Diesel Heaters Use A Lot Of Diesel?

Diesel heaters consume fuel in accordance with their settings and usage. The fuel consumption may vary, but they generally do not consume excessive amounts of diesel. The amount of diesel used depends on factors such as heat requirement, operating time, and efficiency of the heater.

Conclusion

A diesel heater is a efficient and reliable way to keep your space warm. With its simple mechanism and cost-effective operation, it is a popular choice for many people. Understanding the working principle of a diesel heater can help you make informed decisions about using this heating solution in your own home or business.